Label unwinder serves as a crucial device for the storage, distribution, and conveyance of various materials. Our label unwinder is typically comprised of one or multiple tiers of horizontal supports, each designed to hold multiple containers, such as material boxes. The versatility of label unwinder allows for easy adjustments and configurations to meet the diverse requirements of storing and transporting different types of materials. Consequently, these unwinders have found widespread utility across manufacturing, logistics, warehousing, and various other industries.

Within our automated shrink sleeve labeling line, the label unwinder plays a pivotal role. Its primary function is to work in tandem with shrink sleeve labeling machine, facilitating the seamless automation of production processes and the efficient feeding of labels.

-

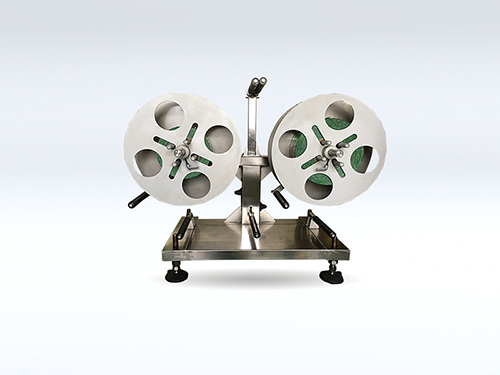

- UWT-240E (dual-reel, T type) UWT-240E T-type label unwinder is designed for use with sleeve labeling machine operating at speeds ranging from 150 to 400 BPM. The label unwinding unit can be conveniently installed above a conveyor belt, saving valuable space. Placing this label feeding unwinder at a height similar to that of an operator allows for easy label roll changing, and the label roll replacement process for this model is simple and time-efficient. Discover More

-

- UWH-240 (dual-reel, H type) UWH-240 H-type label unwinder is widely used in various shrink sleeve labeling applications and can be paired with our shrink sleeve labeling machine of different speeds. This label unwinder features movable casters for easy movement and adjustment of the rack position. Discover More

-

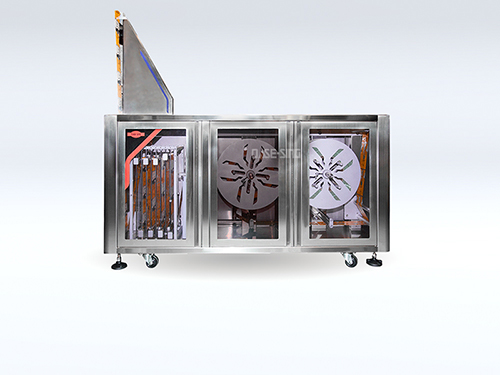

- UWH-320 (dual-reel, fully enclosed) Our UWH-320 label unwinder is designed for thin shrink labels of PET 20μm and shrink labels of PVC 32μm. Paired with a feeding motor, it enables automatic label feeding. The modular and user-friendly design makes equipment adjustments easier and label type changes more convenient, meeting aesthetic requirements. Discover More

-

- UWI-840 (multi-reel) The height is based on the standard layflat width of eight label rolls, and the quantity of label rolls depends on the width of the label being laid flat. This multi-reel label unwinder will continue to operate until the label material is completely depleted, reducing the frequency of label roll changes, increasing productivity, and addressing the issue of frequent material shortages in high-speed labeling machines. Discover More

-

- UWA-240 (non-stop) UWA-240 non-stop label unwinder is typically used in conjunction with a single-head shrink sleeve labeling machine and is equipped with a 43-meter label storage belt, enabling continuous operation of the label feeding unit. The average material changeover time is less than 30 seconds, reducing the frequency of label material changes, increasing production efficiency, and addressing the issue of frequent material shortages in high-speed labeling machines. Discover More