Shrink tunnel is a device used for heat shrink packaging materials and is widely utilized on production lines in various industries, including the food packaging industry, pharmaceutical packaging industry, cosmetics packaging industry, and personal care product packaging industry. The shrink tunnel uses hot air or infrared radiation to heat-treat the packaging material, allowing it to conform to the surface of the packaged item during the shrinking process, resulting in better sealing and protection.

Shrink tunnels offer adjustable temperature and airflow speed, making them suitable for meeting the shrinkage requirements of different materials and packaging items. They also have adjustable feed rates for easy compatibility with downstream packaging production lines. Shrink tunnels can be configured for either unidirectional or bidirectional material feeding, providing flexibility. Additionally, automatic material feeding and collection devices can be integrated to reduce manual labor.

-

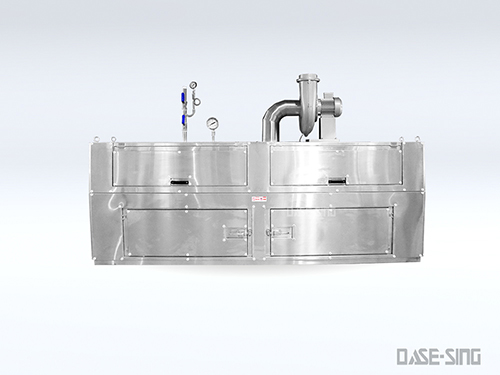

- AS-1800 Steam Tunnel (1.8m, 0.4kW) The steam shrink tunnel uses hot steam to securely adhere shrink sleeves to bottles of various shapes and sizes. Equipped with adjustable steam nozzles and scale markers, it ensures flexible operation and convenient adjustments. The durable stainless steel frame is designed for long-term production and meets the stringent requirements of the food packaging industry. Discover More

-

- AS-2800 Steam Tunnel (2.8m, 0.4kW) AS-2800 shrink tunnel is designed to adhere shrink sleeve labels to containers tightly using hot steam and is suitable for various types and sizes of bottles. The entire machine is constructed from high-strength SUS stainless steel material, making the shrink sleeve more robust and durable, meeting the requirements of the food packaging industry. Discover More

-

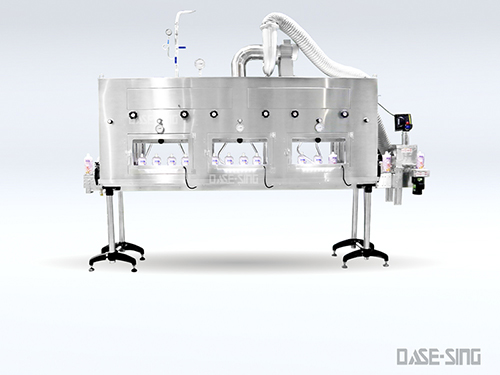

- AST-128B Steam Tunnel (2.8m, 0.75kW) The steam shrink tunnel is a high-performance heat shrink packaging solution designed for bottled products. With a length of 2.8 meters and a stainless steel frame, it is built to withstand various working environments. The tempered glass window allows operators to easily monitor the shrink process inside the tunnel, ensuring consistent packaging quality. Discover More

-

- SH-120 Electric Heat Tunnel (1.2m, 0.4kW) The SH-120 shrink tunnel uses electric heating to shrink labels and securely adhere them to containers. This electric heat shrink tunnel heats up quickly, has low operating costs, and is easy to maintain and disassemble. It is suitable for shrinking label packaging materials made of PVC, PET, OPS, which are applied on bottle caps and containers of various shapes and sizes. Discover More

-

- SH-202 Electric Heat Tunnel (2.2m, 0.4kW) SH-202 shrink tunnel employs electric heating to aid in the shrinking of film around containers, securely adhering it to the container surface. It is suitable for various bottle shapes, including square, curved, and more. Innovatively designed with a side-hanging lifting mechanism and a digital temperature controller, it ensures precise temperature control during shrinking. Discover More