Overview

Oyster sauce packaging in the market is mostly glass bottle packaging, and oyster sauce is thick and not easy to pour, often requiring effort to shake it out.

For Zhongjing Food's new product, Mushroom Oyster Sauce, we adopted a "Small Waist" label design to adapt to their squeeze sauce bottle that is easy to squeeze and control the quantity accurately. The unique bottle shape also retains the narrow neck and long neck design of glass bottles, minimizing contact with air, reducing the risk of microbial contamination, and ensuring cleanliness and hygiene.

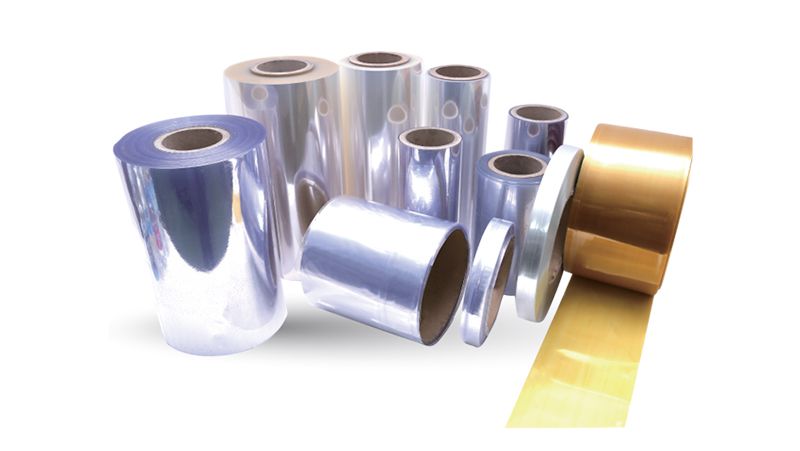

When labeling flexible squeeze bottles, it's important to consider the shrinkage rate and durability of the label material, as it needs to withstand the repeated squeezing by consumers during use. The label covers the entire product from top to bottom, providing more design space and protecting the product.

We understand the needs of our customers and adjust the production line specifications according to their requirements and on-site data. Zhongjing Food uses our DSV-BP shrink sleeve label applicator and sleeve underlapping machine, with a maximum production speed of up to 450 BPM, which can be adjusted according to customer needs. What we deliver to our customers is not just products but also high-quality service. Dase-Sing's engineers have extensive on-site experience and can identify possible causes of issues based on known on-site conditions and propose effective solutions.

Overview

Bottled beverages have long been a preferred choice for many consumers due to their affordability, ease of storage, and portability. Whether for home consumption or outdoor activities, beverages are an essential part of daily life. Regardless of whether a brand requires large-scale production or diverse production to meet marketing demands, our labeling equipment is favored by many manufacturers for its stability.

For Dali Foods Group, a company specialized in manufacturing bottled green tea, we have provided them a tailored solution for labeling their flavored tea bottles. The DSVC-EB II high-speed double head shrink sleeve labeling machine, when used in conjunction with conveyor systems and feeding systems, can achieve a maximum simultaneous production speed of up to 720 BPM with a label length of 180mm. Its standout feature is the ability of the dual heads to simultaneously produce different label products. For example, one head can label the body of the bottle while the other head labels the bottle cap, all on the same production line. Furthermore, if the first head requires maintenance, experiences an issue, or needs a label change, the second head can automatically take over production without reducing efficiency, with a speed of up to 650 BPM with a label length of 180mm.

Subsequent equipment such as steam shrink tunnels and drying systems, also from us, make the labeling line even more stable and complete.

The stable and diverse adjustment options allow customers to independently adjust production capacity according to their needs. Apart from the shrink sleeve labeling machines and peripheral equipment, we take great pride in our high-quality after-sales service. Dase-Sing's equipment is of high quality and runs stably, making work more efficient. Even if on-site conditions change, the high flexibility in adjustments allows the equipment to continue running smoothly.

Overview

In the beverage industry, round and square bottles are common shapes, and almost all labeling machine manufacturers can label these types of bottles. However, as product bottle shapes become more complex, labels must not only complement the bottle shape but also be applied to specific positions without exceeding certain tolerances.

Energy drink products have unique requirements, such as Asia-Lion Extra Strength Drink. To convey a sense of vitality and strength, these products often feature irregular bottles with flowing lines, paired with label designs featuring elements like lion imagery to evoke a sense of energy and power. Additionally, clients may require that the label must be applied to a specific side, ensuring that the label graphics face the same direction.

When precise label placement is required, Dase-Sing's i-Vision label orientation system excels in visual recognition and meets the needs of customers.

i-Vision is a label positioning device designed for various container shapes used to meet market demands. It is suitable for a wide range of unique bottle shapes. When bottles are conveyed to the machine from different angles, i-Vision label orienter helps align all bottles in the same direction for further processing. Importantly, this orientation can occur either before or after filling. During operation, if bottle adjustments are needed, the mechanical device doesn't require stopping; settings can be switched to independently align bottles in the desired direction.

We believe that this label orientation system can meet the needs of customers with specific container shape requirements, such as bottles with handles, streamlined energy drinks, or bottles shaped like animals. These containers often require aligning bottles in a specific direction before labels being applied. We assess these projects and conditions, helping customers determine the optimal label size and type.

Furthermore, i-Vision label orientation system can be configured for standalone operation according to customers' requirements or integrated into their existing production lines.