In order to accommodate the specific needs of filling lines or production lines at customers' plants, we offer several options of shrink sleeve labeling lines to meet the demands.

- High-speed labeling line solutions to increase the production capacity of food and beverage manufacturers.

- Our shrink sleeve labeling systems can seamlessly integrate with other peripheral equipment.

- Highly flexible: bottle capacities ranging from 50 milliliters to 1 liter can be accommodated on our labeling equipment.

- Helping customers solve their problems through straightforward application interpretation and various approaches.

DSVC-BP×1set (for CL<180mm) CL=cut length

Sleeve label applicator speed: 450 BPM with only 12.5 % overspeed

Solution includes

| System Model | Machines | Machine Model | Quantity |

| 24000BPH-1 LINE Shrink Sleeve Labeling Line | Single Head Shrink Sleeve Labeling Machine | DSVC-BP | 1 |

| 2.8m Steam Tunnel | AS-2800 | 1 |

DSVC-EBII×1 set (for CL<180mm) CL=cut length

Sleeve label applicator speed: 480 BPM with more than 20% overspeed

Solution includes

| System Model | Machines | Machine Model | Quantity |

| 24000BPH-1 LINE Shrink Sleeve Labeling Line | Double Head Shrink Sleeve Labeling Machine | DSVC-EB II | 1 |

| 2.8m Steam Tunnel | AS-2800 | 1 |

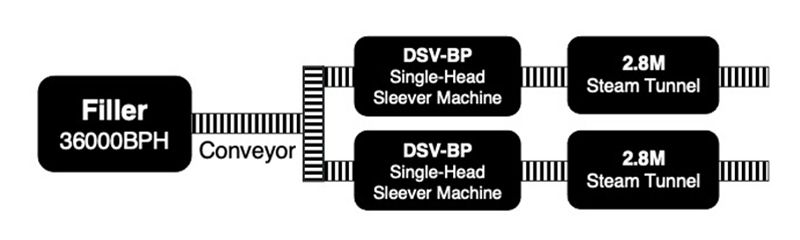

DSV-BP×2 sets (for CL<180mm, only full body/partial body/tamper evident neck band) CL=cut length

Sleeve label applicator speed: 360 BPM per each machine with 20% overspeed, one machine can cover 60% of the production speed when one machine is down.

Solution includes

| System Model | Machines | Machine Model | Quantity |

| 36000BPH-2 LINES Shrink Sleeve Labeling Line | Single Head Shrink Sleeve Labeling Machine | DSVC-BP | 2 |

| 2.8m Steam Tunnel | AS-2800 | 2 |

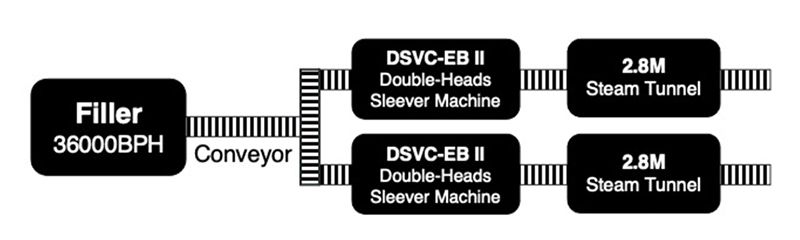

DSVC-EBII×2 sets (for CL<180mm/two types of label at the same time) CL=cut length

Sleeve label applicator speed: If requiring tamper evident neck band and full body sleeve labeling at the same time, each machine can run 360 BPM with 20% overspeed. One machine can cover 60% of the production speed when one machine is down.

Solution includes

| System Model | Machines | Machine Model | Quantity |

| 36000BPH-2 LINES Shrink Sleeve Labeling Line | Double Head Shrink Sleeve Labeling Machine | DSVC-EB II | 2 |

| 2.8m Steam Tunnel | AS-2800 | 2 |

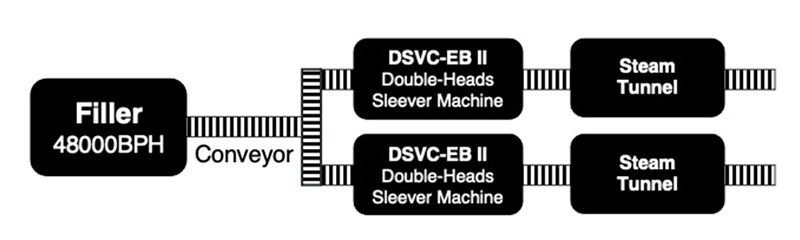

DSVC-EBII×2 sets, CL=cut length

Sleeve label applicator speed: each machine run at 480 BPM with 20% overspeed, one machine can cover 60% of the production speed when one machine is down.

Solution includes

| System Model | Machines | Machine Model | Quantity |

| 48000BPH-2 LINES Shrink Sleeve Labeling Line | Double Head Shrink Sleeve Labeling Machine | DSVC-EB II | 2 |

| Steam Tunnel | AS-2800 | 2 |

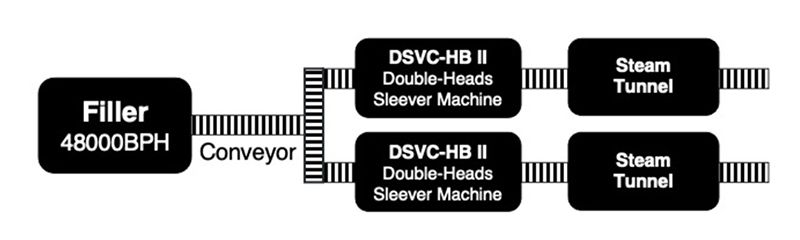

DSVC-HBII×2 sets (for CL<180mm/two types of label at the same time) CL=cut length

Sleeve label applicator speed: each machine run at 480 BPM with 20% overspeed, one machine can cover 60% of the production speed when one machine is down.

Solution includes

| System Model | Machines | Machine Model | Quantity |

| 36000BPH-2 LINES Shrink Sleeve Labeling Line | Double Head Shrink Sleeve Labeling Machine | DSVC-HB II | 2 |

| Steam Tunnel | AS-2800 | 2 |

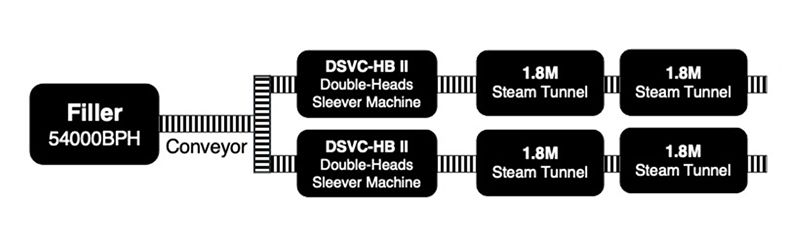

DSVC-HBII×2 sets (for CL<180mm, only full body/partial body/tamper evident neck band) CL= cut length

Sleeve label applicator speed: each machine run at 540 BPM with 20% overspeed, one machine can cover 60% of the production speed when one machine is down.

Solution includes

| System Model | Machines | Machine Model | Quantity |

| 48000BPH-2 LINES Shrink Sleeve Labeling Line | Double Head Shrink Sleeve Labeling Machine | DSVC-HB II | 2 |

| 1.8m Steam Tunnel | AS-1800 | 4 |

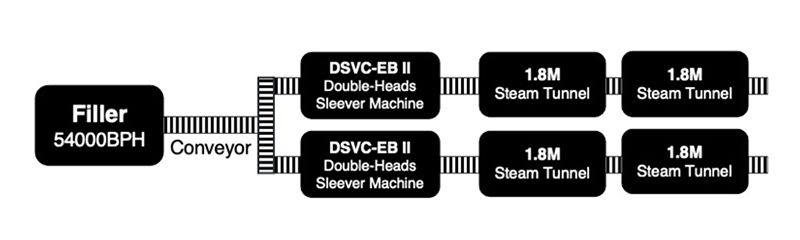

DSVC-EBII×2 sets (for CL<180mm/two kind of label at the same time) CL=cut length

Sleeve label applicator speed: each machine run at 540bpm with 20% overspeed, one machine can cover 60% of the production speed when one machine is down.

Solution includes

| System Model | Machines | Machine Model | Quantity |

| 36000BPH-2 LINES Shrink Sleeve Labeling Line | Double Head Shrink Sleeve Labeling Machine | DSVC-EB II | 2 |

| 1.8m Steam Tunnel | AS-1800 | 4 |